Polyurethane Injection Grouting Waterproofing Solutions

Home / Polyurethane Injection Grouting Waterproofing Solutions

At Adcos asia, we provide a comprehensive range of specialised chemicals designed to tackle water ingress and structural leakage repairs, including polyurethane injection grouting.

Polyurethane injection grouting is a highly versatile material used to seal cracks in concrete, masonry, and screed, particularly in areas subject to water penetration. This two-component system—consisting of a polyol and isocyanate component—reacts to form a durable, expanding sealant. This system ensures that water is blocked from entering cracks and joints, providing an effective and long-lasting solution for structural waterproofing.

What You Need To Know About PU Grouting & PU Injection

Polyurethane (PU) grouting is a specialised technique involving the injection of expanding polyurethane to prevent moisture from seeping through cracks or to fill voids under slabs or behind concrete walls and joints. This method, also referred to as PU foam injection, is particularly effective in sealing active leaks in structural elements.

The PU grout is injected into a pre-drilled hole to fill voids, seal leaks, and strengthen the surrounding substrate. Subsequently, the grout will expand to fill any crevices that are caused by water damage. This PU injection method is commonly used for concrete cracks or expansion joints that are actively leaking.

Advantages of PU Foam Injection for Structural Waterproofing

PU foam injection offers distinct benefits in both restoration and waterproofing for larger infrastructure and commercial projects:

Fast-Acting and Expansive

The foam rapidly expands upon contact with moisture, ensuring immediate sealing of leaks and voids, even in inaccessible areas.

Durable and Flexible

Once cured, the foam retains flexibility while forming a resilient waterproof barrier that withstands structural movement, vibrations, and temperature variations.

Minimal Downtime

Application requires no major hacking or structural modification, allowing works to proceed with minimal disruption to operations.

Long-Lasting Protection

Resistant to chemicals, moisture, and environmental wear, PU foam injection provides lasting defence against future water ingress and structural degradation.

Versatile Applications

From basements and tunnels to rooftops and water tanks, it is suitable for varied environments across public and private infrastructure.

Types of PU Injection Resins

The type of polyurethane resin used in injection grouting depends on the environment and severity of the leak:

Hydrophilic Polyurethane Injection Resin

Designed to absorb water and expand within cracks, hydrophilic resins are suitable for dynamic conditions where moisture levels fluctuate. Ideal for hairline cracks and non-pressurised water ingress.

Hydrophobic Polyurethane Injection Resin

These resins repel water and expand rapidly, making them ideal for high-pressure water ingress. Commonly used in underground and high-flow conditions, such as tunnels and retaining walls.

Both systems form part of our engineered PU injection grouting services, offering durable solutions for complex waterproofing challenges.

Understanding the PU Injection Grouting Process

Using advanced PU grout technology, polyurethane injection grouting offers a precise and effective method to seal cracks and voids. The resin reacts with moisture to expand, forming a durable, watertight barrier. This technique is ideal for structural waterproofing in tunnels, basements, and underground infrastructure.

Step 1: Site Assessment

Before commencing injection, a thorough site assessment is conducted to identify the cracks and leaks that need to be sealed.

Step 2: Drilling and Injection

Holes are drilled at strategic points where the cracks are located. The polyurethane resin is then injected under pressure into the affected areas.

Step 3: Expansion and Sealing

Once injected, the polyurethane expands to fill cracks, voids, and joints, creating a water-tight seal. The material then hardens, providing long-lasting protection against water ingress.

Step 4: Curing and Final Inspection

The injected polyurethane resin cures and solidifies, completing the sealing process. A final inspection ensures that all cracks are fully sealed and the area is protected.

Applications of PU Injection Grouting Services

Here at Adcos Asia, PU injection grouting services are engineered for a wide range of civil, industrial, and government infrastructure projects. These systems offer targeted, durable waterproofing for structures exposed to hydrostatic pressure, ground movement, and prolonged moisture.

Concrete Repair and Rehabilitation

Our solutions restore structural integrity in damaged concrete elements such as beams, walls, columns, and slabs. Curtain grouting and direct crack injection prevent further deterioration by sealing internal voids.

Tunnels and Underground Structures

PU foam injection is highly effective for active leaks in tunnels, MRT systems, and utility culverts. It seals hairline and expansion cracks in tunnel linings, diaphragm walls, and sheet piles with minimal disruption.

Water Retaining Systems

Used in reservoirs, swimming pools, water tanks, and treatment plants, PU resins are formulated to be safe for potable water and resistant to constant immersion.

Basements and Foundations

PU injection grouting services address basement seepage and rising damp, offering a robust solution for commercial carparks, lift shafts, and retaining walls.

Roof Decks and External Areas

Flexible PU systems are used on roofs, terraces, and facades to protect against thermal stress and cracking caused by weather exposure.

Our team brings over 30 years of proven experience in leak sealing and structural waterproofing across Singapore’s built environment.

Residential Leakages

Leak sealing of tunnel segments and joints.

Leak sealing of diaphragm wall, sheet pile and bore piles.

Leak sealing of cracks, joints and porous concrete structures.

Leak sealing of potable water and chemicals retaining structures.

Residential Leakages

Our team of certified and highly skilled workers have more than 30 years of experience in leak sealing and concrete repair solutions. Let us help you alleviate your worries and stress from these problematic water leakage issues with our tried-and-tested, effective and durable solutions.

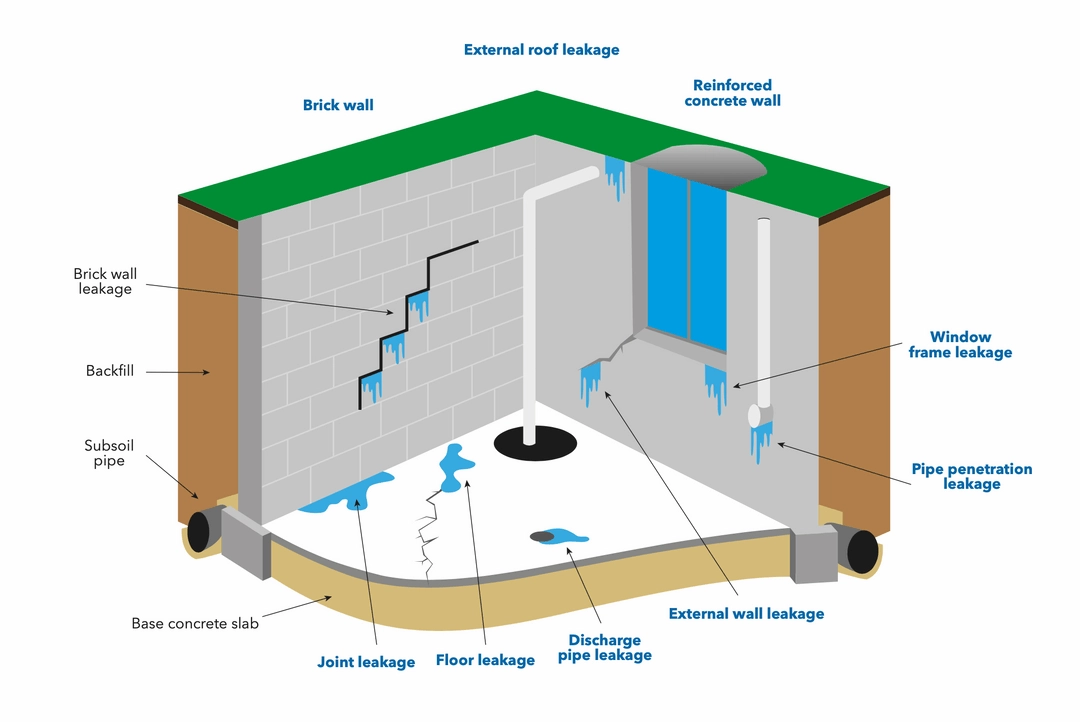

We can help you fix problematic water leakage issues in your Estate, including:

Underground Structure — basement carparks, garages.

Wet Areas — toilets, kitchens, window frames, terraces, gardens, planters, bedrooms walls, ceilings.

Water Retaining Structure — swimming pool, water tanks.

Roof — concrete, tile, or metal roof.

As long as there’s a water leak, you can count on Adcos Asia to have it fixed.

What Are The Common Causes Of Building Cracks

1. Poor Drainage

Inadequate drainage systems often lead to water seepage, which can weaken concrete and other building materials over time, causing cracks to form.

2. Heavy Loads

Heavy machinery or vehicle traffic can damage structures, particularly in areas subjected to constant stress, leading to cracks in walls and floors.

3. Wear and Tear

Over time, exposure to the elements causes natural wear and tear on buildings, particularly in high-moisture areas. Without regular maintenance, this can result in cracks and structural weakness.

Epoxy Resin Injection

Epoxy resin injections are used for their superior bonding capabilities and resistance to water and chemicals. These systems are ideal for repairing structural damage in tunnels where high durability is required.

By using PU injection grouting services, these cracks can be effectively sealed, restoring the building’s integrity and waterproofing.

Future Applications of PU Grout Technology

As construction practices evolve, the future of PU grout technology and PU foam injection lies in its adaptability across advanced infrastructure requirements:

Sustainable Urban Drainage Systems (SUDS)

PU foam injection will play a role in waterproofing below-grade retention systems, especially in flood-prone smart city designs.

Green Roof and Smart Building Integration

As more commercial structures adopt green roofs and vertical gardens, PU grout technology offers a reliable waterproofing method for these moisture-sensitive installations.

Infrastructure Retrofitting and Resilience Upgrades

Older tunnels, MRT stations, and reservoirs can be reinforced with minimal excavation using targeted PU injection methods to extend service life.

Digital Integration and Smart Monitoring

The integration of smart sensors with injection systems may allow remote monitoring of moisture ingress and trigger PU injections proactively in high-risk zones.

FAQs

How long does polyurethane grout take to cure?

PU foam injection typically cures within 24 to 48 hours. The speed of curing may vary depending on the type of resin used, site moisture levels, and environmental conditions.

How long can a PU injection last?

A PU injection can last for many years, often up to 20 years or more, depending on the application, environmental conditions, and quality of the installation. Regular inspections can help maintain its effectiveness over time.

Can you use polyurethane as grout?

Yes, polyurethane can be used as a grout, especially in situations where flexibility, waterproofing, and chemical resistance are needed. It is particularly effective in areas prone to movement or where traditional grout might crack.

How long does polyurethane grout need to cure?

Polyurethane grout typically needs about 24 to 48 hours to fully cure, though this can vary depending on the specific product and environmental conditions. Proper curing ensures maximum strength and durability.

Is PU foam injection safe for potable water areas?

Yes. Specific polyurethane resins used in PU foam injection are certified safe for use in structures like drinking water tanks and reservoirs.

What structures are suitable for PU injection grouting services?

These services are ideal for tunnels, basements, water tanks, retaining walls, and other infrastructure exposed to hydrostatic pressure or structural cracking.

Can PU injection grouting be used while facilities are operational?

Yes. Many PU injection grouting services are non-disruptive and can be carried out in operational environments such as commercial carparks or underground MRT stations.

How is PU grout technology different from traditional waterproofing methods?

PU grout technology offers targeted, minimally invasive repairs with superior flexibility and chemical resistance. Unlike sheet membranes or coatings, it seals leaks from within the structure.

ADCOS Asia

ADCOS Asia